Mandrel

Mandrels are used as internal support for tube bending and their purpose is to mitigate defects such as flattening or crinkling of the inner radius of the bent tube. Selecting the proper mandrel type is critical to produce the desired bend. This selection depends mainly on the outer diameter pipe (OD), wall thickness (WT), and bending radius (CLR). The correct setup of the mandrel is another important factor for a successful bend.

Selecting the proper mandrel type is critical to produce the desired bend. This selection depends mainly on the outer diameter pipe (OD), wall thickness (WT), and bending radius (CLR). The correct setup of the mandrel is another important factor for a successful bend.

Simple plug

This type of mandrel is suitable for strong walled tubes bent around a large radius.

Simple formed plug

This type is intended for similar applications as the simple plug, but the shaped part of the mandrel provides better support for the tubes on the outer radius of the bend.

Standard mandrel

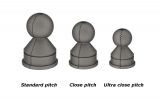

As the name suggests, standard is one of the most widely used mandrels and provides sufficient support for common bending parts.

Close pitch, thin wall mandrel

This type is used in the bending of thin-wall tubes with smaller bend radii. The size of the coupling unit is one size smaller than in the a standard mandrel and the bearings are close together. This configuration provides greater support during the bend.

Ultra close pitch, Ultra thin wall mandrel

These are suitable for tube bending of very thin walls and very small radius bends. Similar to the thin-walled ball mandrel, it has a smaller size of connected parts.

Links

Links have a very important role on ball mandrels because they connect the balls to the shank. Selecting the proper links for your mandrel can have a significant impact on the life of the mandrel, so it is very important to always use the correct mandrel and implement proper assembly and setup.

As the balls are arranged closer together on the thin-walled and ultra thin-walled mandrels, the firmness of the links is compromised.

In terms of functionality, it is very important to use suitable materials for the tube, and setup the mandrel properly. For more information regarding mandrel functionality, please see more here: Tube Bending Guide.